Why GenRight Suspension?

When GenRight was born in 2006, founder and off-road racer Tony Pellegrino quickly learned that stock and most aftermarket components just wouldn’t hold up to the reliability and performance needed for extreme driving conditions.

So, GenRight decided to develop our own parts that would perform reliably in the most extreme situations. Our love of racing further accelerated the research and development program by putting designs, materials and parts to the ultimate test.

Decades later, GenRight Off Road built Jeeps have become iconinc in both on and off-road vehicles that competitor companies can only dream of emulating.

LET'S THINK ABOUT IT...

Things you want in a suspension system

- The ability to run bigger tires -

- Increased ground clearance -

- Stability -

- Reliability -

- The Jeep to be road-worthy -

- A quality ride that provides performance on & off road -

In order to achieve this, we get rid of the stock frame mounting brackets and replace them with our brackets, that are twice as thick as stock, and welded on, not bolted on like most aftermarket suspension kits.

PLUS we design all of our suspension systems using SolidWorks, with factory Jeep models, for a precision fit and flawless assembly.

WE USE QUALITY MATERIALS

Everything included in all of our Suspension Systems has been Trail Tested & Race Proven for over 15 years. We implement specific products into every system we offer.

• Genuine Currie Johnny Joints

• 4130 Chromoly or 7075 billet link arms

• All grade 8 hardware

• Uni-Torque nuts

• 3/16” - 1/4” cold rolled laser cut steel brackets & mounts

We’ve tested our product under the toughest trail AND race conditions, and we found the best matches for the reliability, performance, and comfort that we will not sacrifice.

LET'S TALK SHOCKS...

We replace the stock coil spring setup with coil over shocks that maximize space, and provide a luxurious ride with optimal performance both on and off road. These are available in a 2.0", 2.5", or 3.0" diameter with a 12" or 14" stroke.

Our coil over shocks (King, Fox, Bilstein) are custom valved by the manufacturer to perform flawlessly with our suspension geometry.

We also place the shock mounts on the axle as far outboard (to the wheel) as possible. This gives you maximum dampening control, stability, and adjustability.

LET'S TALK AXLES...

Our systems were designed around the Currie Dana platform (mainly 60/70)

The rolled back differential cover provides more room for a lower ride height, and offers more protection from getting peeled off by rocks.

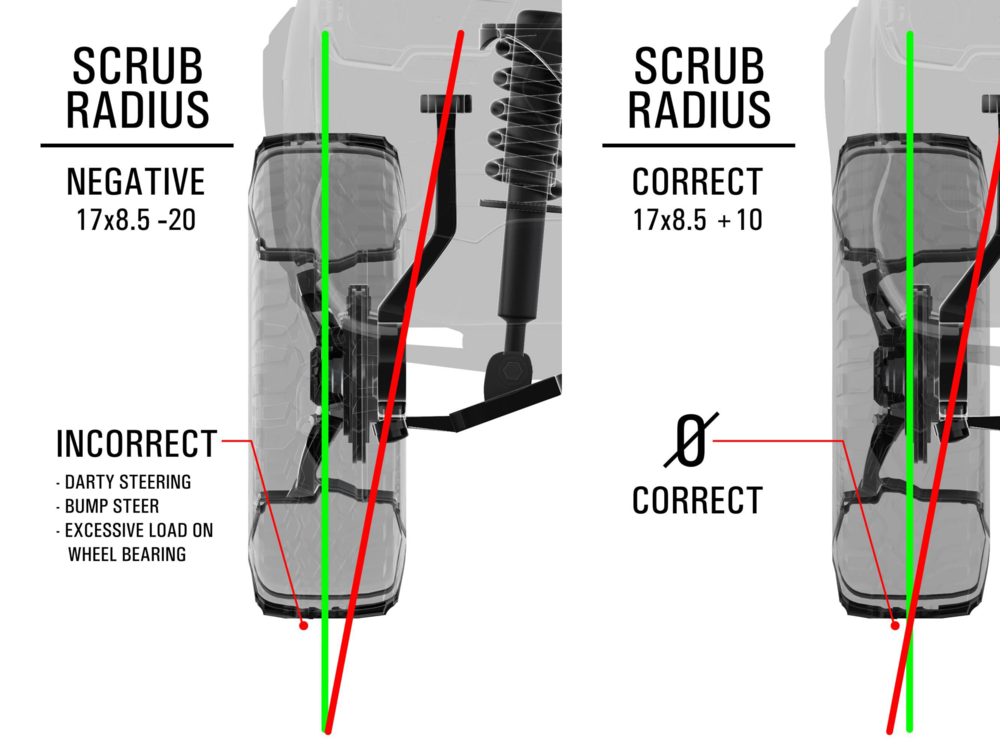

These axles are wider than stock, have bigger brakes to stop bigger tires, and allows for more backspace on the wheels to reduce scrub radius.

The axles we use are built to GenRight’s specs with the proper castor and differential offset to increase stability and control. Additionally, we weld-on true high-steer parts with Ram assist in the proper location on the axle to protect the steering and easily move bigger tires.

NO MORE DEATH WOBBLE!

A common problem with other kits is that they don’t account (or care about) the fact that when you lift your Jeep using the factory mounting locations, it changes your front axle castor, and this will bring you’re worst nightmares to life on the highway.

This is why GenRight designs our suspension kits as a "system" so that we know the geometry is right, and that the components are reliable.